Underpinning

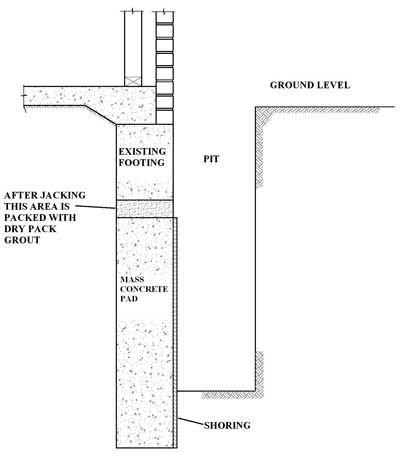

Mass Pads

This is where a Pad, or a pit is dug under the existing footing which can be any where up to 2 metres long, 1 metre wide and 2 metres deep. This is normally dug by machine or by hand if there is not enough room for a machine. The pad is dug further under the existing footing to the width of that footing.

Once the required depth is reached, as per the engineers report, concrete is poured leaving a void between the new concrete footing and the old footing. This void is where a jack is placed for jacking to bring the walls of the building as close to original level as possible. Once the building is jacked to as close as original level the void is packed with dry pack grout and the pit is backfilled.

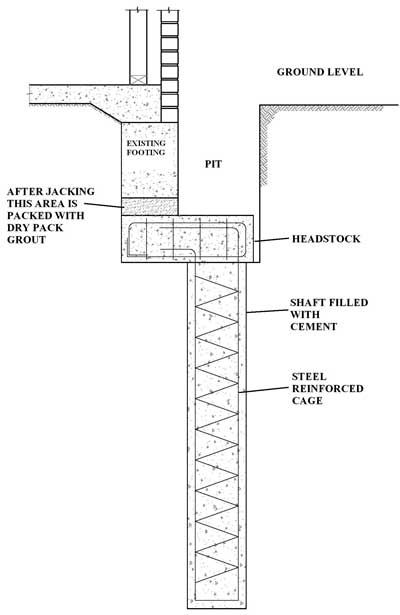

Bored Piers

This is perhaps the most popular form of underpinning as it allows you to drill down to great depths to find bearing capacity, as per engineer specifications, for new footings. We have the capability to drill piers from 75mm to 750 mm in diameter and up to 10 metres in depth with our vast array of machinery. We have drilling rigs to suit all conditions from commercial drilling machines to portable rigs that can be used inside restricted areas when ceilings are as low as 1.8 metres, for example, inside your home. These portable rigs have the capability of drilling down to a 6 metre depth.

Firstly, a small pit is dug to a depth of 600 – 700mm below the bottom of the existing footing. Then we proceed to drill to the required depth as per your engineer’s specification. Once we are at the required depth we will dig under the existing footing to the width of that footing.

A steel reinforcing cage the depth of the pier is then placed down the pier with another cage known as a headstock joined from the top of the cage to underneath the existing footing. The pier is then filled with concrete which covers the headstock. A void is left between the top of the headstock and the bottom of the existing footing. This void is where a jack is placed for jacking to bring the walls of the building as close to original level as possible. Once the building is jacked the void is packed with dry pack grout and the pit is backfilled.

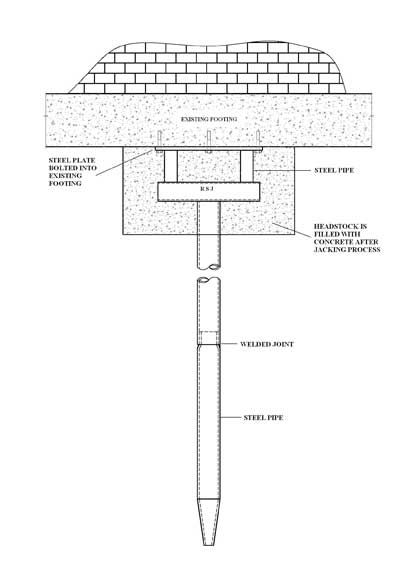

Jacked Piles

Jacked Piles is a method of underpinning for use below footings founded on weak fill spoil overlaying strong stratum, hard clays or weathered rock. This form of underpinning is particularly suitable for limited access situations where there is no room for drilling rigs of any capacity. The depth attainable by these jacked piles is directly related to the proof loading the building can sustain. It is not recommended for residential housing as this method relies on the weight of the building to reach the required loading capacity.

A pit known as a headstock is dug to a depth of 1300mm below the existing footing. The width of the headstock is the width of the existing footing.

Steel pipes of 1 metre length ranging from 170mm – 300mm in diameter are then driven down via a hydraulic jack. These metre length pipes are welded together until the required depth, as per your engineers report or the proof loading, is reached. Once that depth is reached, the pile is concrete filled and steel reinforced if required. An RSJ is welded to the top of the pipe and then 2 steel pipes are welded from the RSJ to a steel plate that is bolted into the existing footing which gives the existing footing and the building the support it requires.

The pit is then filled with concrete and backfilled.

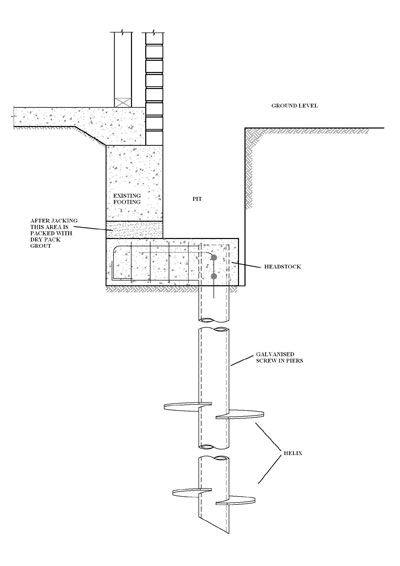

Screw Piles

This method of underpinning is particularly effective in unstable soils, particularly sand, moist and highly reactive soils and works similarly to the theory of the bored piers. After the pit is dug, galvanised steel piles are screwed into the ground using a machine specially designed for this purpose to the depth required as per your engineer’s specifications.

These piles can attain a depth of up to 15 metres. The centre of the steel pile is then filled with concrete and as with the bored piles, the top is then tied into the headstock. The headstock is then covered with concrete. A void is left between the top of the headstock and the bottom of the existing footing. This void is where a jack is placed for jacking to bring the walls of the building as close to original level as possible. Once the building is jacked the void is packed with dry pack grout and the pit is backfilled.

These piles can also be used as a method of support for new structures and slabs.

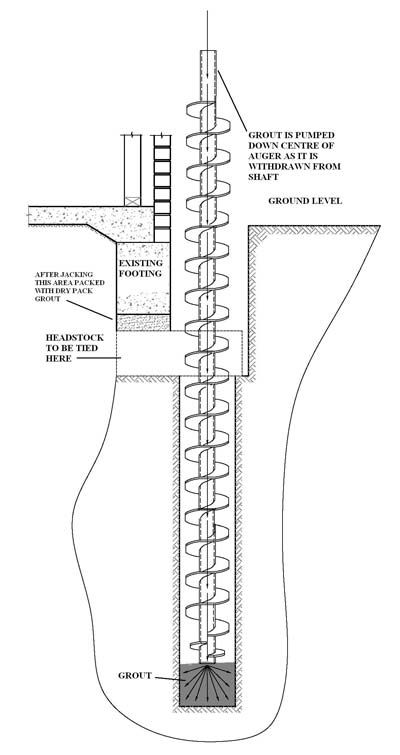

Grout Piles

Grout Piles are the ideal solution when the failed footings are located in sand. The theory is very similar to bored piers but unlike bored piers when the augers are removed from the ground the pier is prone to collapsing because it is drilled in sand. With this method we can drill piers to a depth of 10 metres with a diameter of 450mm. As with bored piers we dig a pit 600mm – 700mm below the existing footing with the width of the pit being the width of the existing footing.

There is difference between the augers that we use for grout piles and bored piers. The difference is the augers used for grout pile have a hole with a 100mm diameter running down the centre of the auger. After we have achieved the required depth for the pier, as per your engineer’s specifications, we place a hose in the hole down the centre of the auger. Before removing the auger from the hole we pump what is know as acquagel down the auger. This process firms up the side of the pier and stops the sand from collapsing. Once the acquagel reaches the top of the pier we then pump grout through the hoses while the augers are being withdrawn.

After this procedure we drive the steel reinforced cage into the grout for extra support. The procedure then follows the standard of tying a steel headstock from the top of the cage to underneath the existing footings. One the grout is set we pour concrete into the pit leaving a void between the new concrete and the existing footing for jacking purposes.

QBCC Lic No: 19036

NSW Lic No: 175383C

ABN: 61 010 459 542

© R & M Monteverde PTY. LTD. All rights reserved.