R. & M. Monteverde Pty. Ltd. is Queensland’s oldest and most experienced underpinning contractor, with over fifty years of experience in a wide range of commercial, industrial and domestic projects. Our company is fully licensed, with skilled and qualified staff who are experts in solving difficult foundation and masonry problems. The companies two directors, Ron Monteverde is a registered open builder and Robert Monteverde is a registered open house builder.

We are skilled in a variety of underpinning and restoration techniques, including mass pads, drilling, bored piles, jacked piles, screw piles, grout piles, pressure grouting and lime stabilisation with the company undertaking approximately 150 projects annually throughout Queensland and Northern N.S.W.

What is Underpinning?

Underpinning is the process of supporting the footings of an existing building at a greater depth. Underpinning is often necessary where the quality of the original soil is poor. The original founding material may be of poor quality because:-

- It was loose or was poorly compacted fill

- It is reactive, that is it moves with changes in moisture content

- It is being eroded by water, slope instability or neighbouring excavation

How do I know if my home or building needs Underpinning?

If there is damage in your building in the form of:

- Cracks in masonry

- Cracks in wall and ceiling linings

- Doors out of square and/or binding

- Floors are out of level

Then you may have a foundation problem that could be corrected by Underpinning.

What do I do if my home or building needs Underpinning?

The first step is to contact us to discuss your problem, after an inspection we can put you in contact with one of several experienced engineers to determine the cause of the movement or damage. They may well recommend Underpinning to correct the problem.

About Us

Our company is committed to providing consistent quality in our services, including:

- Understanding the needs of our industry and our customers

- Selection and training of staff, subcontractors and suppliers to maintain high standards

- Planning and control of on site and off-site processes

- Commitment to health and safety management

- Control of waste, and regard for our environment during all processes

- Monitoring our customers’ level of satisfaction after completion of work

- Commitment to continuous improvement.

We are concerned that both our immediate customers and product end-users all benefit from the quality of our work.

We are fully aware of all current legislation including Workplace Health and Safety for which we have regular training meetings. We are a Quality Assured Company, which is audited annually by independent auditors. All our work is lodged with registered private certifiers for approval.

R. & M. Monteverde Pty Ltd is a member of the Queensland Master Builders Association from whom we receive regular updates regarding changes in legislations, building codes and new innovations etc. We also receive regular correspondence from Building Services Authority regarding industry trends, changes in contract documentation and all relevant building code changes that are important in the building area.

Other Services

One sure sign that your home may require underpinning is when you can see cracks in your brickwork or internal walls. This is caused from movement in certain areas of the existing foundation while other areas may not be moving thus parts of your walls will separate and leave gaps.

Once the underpinning process is complete and the concrete has had time to settle, which we normally allow a minimum of 7 days, we will come back and jack your building where we have completed the underpinning.

This is done by placing hydraulic jacks between the new footings we have created and your existing footings. These jacks have the capability of moving a 50 tonne capacity. We do not jack from one pin alone e.g. if we have done 10 new pins, we will use 10 jacks for the process therefore creating an equal and smooth lift.

We always attempt to jack your home or building back to its original level, trying to close up all the cracks but sometimes this is not always possible as your original footings may be weak and brittle and may not be able to handle the pressure from the new stable footings we have created.

Once your house or building is back to original level or as close as possible to that level, the jacks are removed and steel plates are inserted into the void for support and the void is then packed with dry pack grout to stop any movement between the old footing and the new pin.

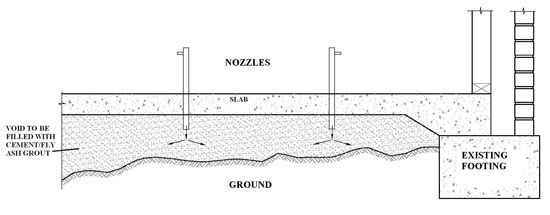

Pressure Grouting is used when the soil under your existing slab subsides which leaves a void between your floor or slab and the ground below it. This void sometimes leaves cracks in your floors, can cause doors and windows not to open and cause visible gaps between the floor and door frames.

Residential Pressure Grout

The process of Pressure Grouting involves the injection of cement/fly ash grout into the voids to fill that gap which provides support to the slab. This is achieved by drilling holes into the slab at spacings of 1.5m to 2.5m, depending on the size of the slab. Nozzles are then placed into these entry points and then the cement/sand grout is pumped via hoses through the nozzles underneath the slab.

This process is used to stop any further subsidence of the slab. The re-levelling of the slab can sometimes be achieved provided a seal can be maintained around the perimeter of the slab.

A major cause of foundation movement is when moisture reacts with the clay around your existing footings. It can also cause movement to any slabs or paths that are laid around the perimeter of your home. The process of using a moisture barrier is predominately aimed at remedial works for the distress caused by this moisture.

The process involves digging a trench to a depth anywhere between 600mm to 2 metres, depending on your engineer specifications, and is normally 200mm wide. Once the trench is dug layers of Micron PVC are placed down the inside of the trench on the side closest to your dwelling. This Micron PVC also covers the ground between the trench and your dwelling allowing you to replace any slab or concrete path that has been effected by movement.

Once the Micron PVC is in place the trench is filled with concrete. Your engineer will specify that a slab is to be laid next to your dwelling that becomes the moisture barrier. This slab along with the micron PVC prevents any moisture from seeping into your existing footings which may cause movement.

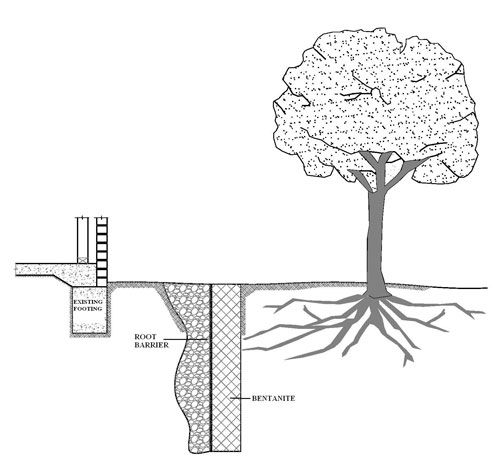

Another cause of foundation movement is tree roots. Underground roots can grow towards your foundations and suck all the moisture content out of the soil around your footings causing these footings to fail. The roots can also cause your plumbing pipes to break releasing moisture into the soil around your foundations.

If this issue is detected early it may prevent from having to underpin your property.

The concept of a root barrier is very similar to that of a moisture barrier. The process involves digging a trench to a depth anywhere between 600mm to 2 metres, depending on your engineer specifications, and is normally 200mm wide. Once the trench is dug layers of hard plastic, known as root barriers, are placed down the inside of the trench on the side closest to your dwelling. The trench is then filled with a substance called Bentanite. This plastic along with the bentanite is so durable that it prevents any tree roots passing through it, diverting their growth away from your footings.

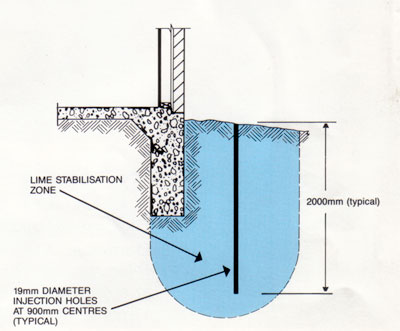

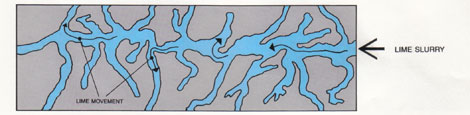

We have been carrying out lime stabilisation since 1985 throughout Queensland and Northern New South Wales. This process is predominately aimed at remedial works for distress. During this period, experience has allowed for the development of the lime stabilisation process where it can be offered as an effective and cost reduced alternative to other forms of work such as Underpinning.

The process of the work is very similar to pressure grouting with lime as opposed to grout being pumped into the area required.

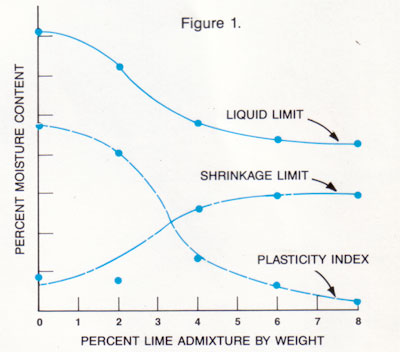

The addition of small qualities of lime to expansive clays will reduce the plasticity of the soil and its swelling potential. Lime drastically reduces the expansive potential of clay soils. Expansion of soil is a major factor in foundation movement which most times will lead to the requirement of underpinning on your property.

Over the years we have developed many different types of machinery for various projects we have undertaken.

We now have machinery that is capable of drilling for both commercial and residential projects.

These machines are capable of drilling to whatever depth your engineer requires with piers from 200mm to 750mm in diameter.

We have machinery that can work inside your home needing only a clearance of 1.8 metres in height, we even have small ride on drilling rigs that can work inside your garage and get to places where our larger machines cannot go. The advantage of these machines is that we can have your job finished a lot quicker than our competitors can.

“We Underpin Queensland”

Testimonials

Mr.JIM B.

“… . All the aspects that I could observe:

- measures taken to ensure the safety of my family near the site

- care and tidiness of the soil that had to be stored on my driveway, and the steps taken to ensure it did not enter my stormwater system

- the thoroughness of the process of removing the excess soil and leaving our driveway absolutely.clear

- the reduction of the gap in the plaster in the ensuite were done very professionally….”

Mr. TED C.

Mr. W.K.

GEORGE & DOROTHY N.

Contact Us

-

(07) 3277 9953

-

37 Boyland Avenue, Coopers Plains, Q. 4108

-

P.O Box 123, Salisbury, Q. 4107

QBCC Lic No: 19036

NSW Lic No: 175383C

ABN: 61 010 459 542

© R & M Monteverde PTY. LTD. All rights reserved.